Snapshot

Batch.Works, a prototyping and product design company, identified the opportunity to tackle the issue of single-use plastic waste for their corporate clients, leveraging their 3D printing abilities and facilities.

They were awarded a £15k grant by ReLondon from the GLA’s Green New Deal fund, to progress work with a major UK retailer to demonstrate how waste might be processed to create new, usable products for their stores – and in the process develop a repeatable service for other clients.

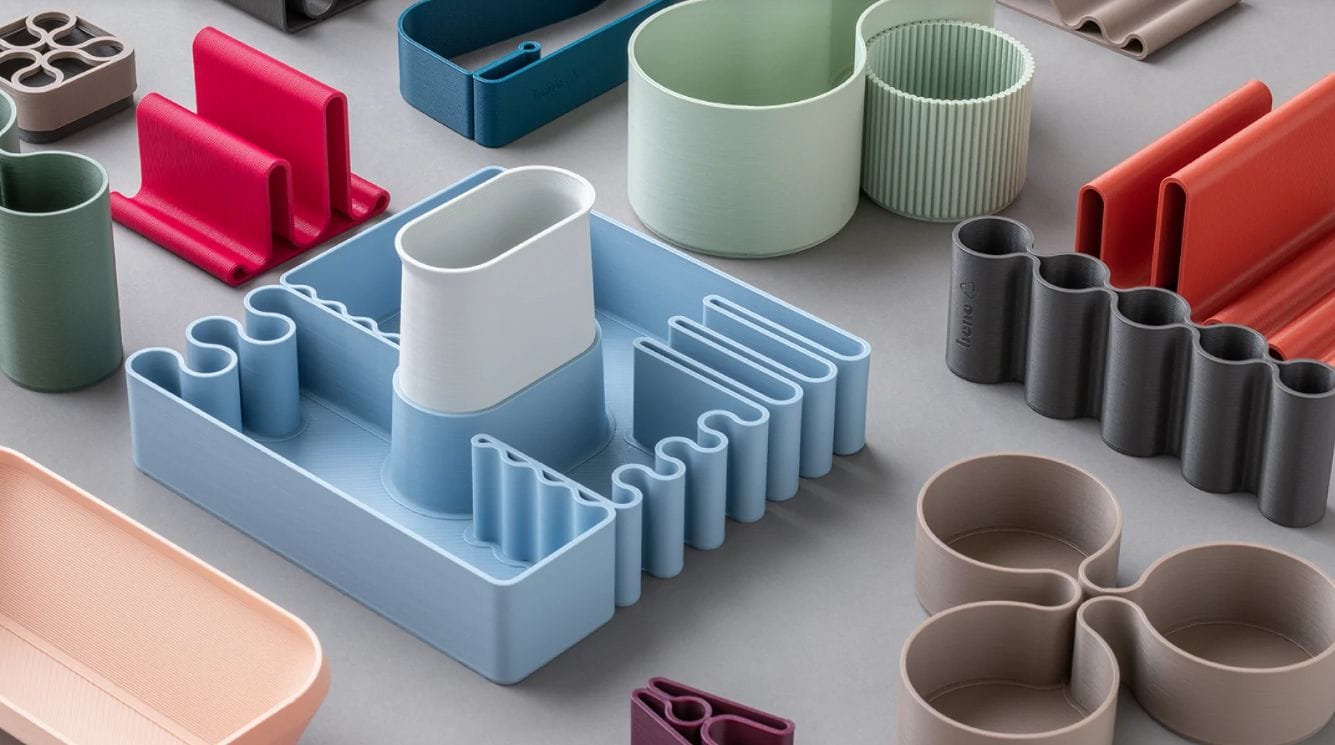

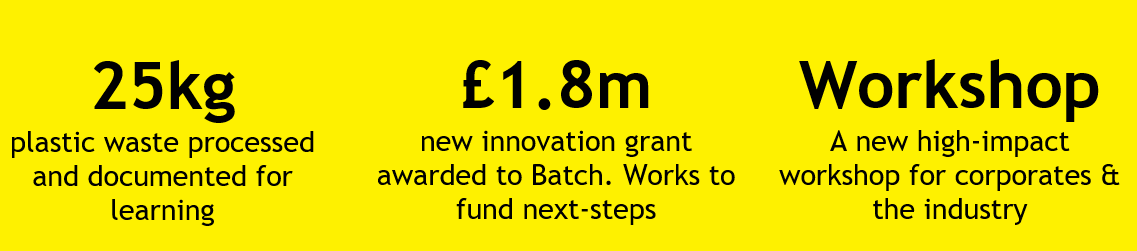

The project led to the design of a new, successful workshop to engage with potential clients. They demonstrated their concept by processing 25kg of the partner’s waste material and showing how equivalent recycled material can be used to create impactful point-of-sale displays in stores.

With big plans for the future, Batch.Works will continue this work having recently been awarded an innovation grant of £1.8m to create a network of manufacturing hubs that will use local recycled materials.

What was the challenge?

Batch.Works is a London-based, rapid prototyping and product design company that helps retail, tourism and fashion clients make 3D-printed products. Since 2018, they have designed 100 products and 3D-printed over 100,000 units, working with clients across the UK including large organisations such as Paperchase, V&A and Tate Modern.

One of their clients, a major high-street retailer in the UK, approached them about the issue of single-use plastic waste generated at their partner stores and offices across the country. Through discussion, Batch.Works identified the opportunity to develop a new service that would help them create value from their waste stream: to transform plastic waste into new products that could be sold in stores.

What was the response?

Batch.Works decided to proceed with the research, design and development of a new commercial service creating plastic products made from waste, using their 3D printing technology.

To develop this new service, Batch.Works needed to understand whether it would be possible to source plastic waste from within the retailer’s supply chain that met the cleanliness and other standards needed to turn them into sellable products. They also needed to develop manufacturing processes that would be viable and attractive to large retailers.

ReLondon were pleased to offer them a grant of £15,000, thanks to the Mayor of London’s Green New Deal fund, to trial the new service from October 2021 to April 2022. In that time, Batch.Works was able to run an entire cycle of the service – from auditing a batch of their partner retailer’s plastic waste, designing options, and processing and 3D printing the plastic waste into new products.

Along the way, Batch.Works found that it was necessary to inform and educate potential clients about the benefits of taking this approach – particularly as this new service challenged the partner retailer’s successful, but “traditional”, business model. To make the service successful, staff members at the retailer would also need to work differently, adopting new processes and mindsets. To help bring employees on board, Batch.Works designed and facilitated a workshop to raise awareness of the opportunities around distributed manufacturing with recycled materials. While this is an on-going process, they found that the session helped to make strong progress in the attitude and adoption of the concept.

Once they had secured broader buy-in, they then needed to secure a consistent plastic waste stream that would work upon scaling-up the process and delivering this in-house.

Milo Mcloughlin-Greening, Batch.Works, Research & Sustainability OfficerWorking with established brands can be challenging, but we’ve found that bringing key people together for hands-on workshops helps break down barriers – seeing really is believing.

What were the outcomes?

This pilot has been instrumental in helping Batch.Works engage with businesses that recognise their contribution to the plastic waste problem, and refine the business model for a new service.

In the 6 months of the pilot, they were able to audit and process 25kg of plastic waste and use this information to demonstrate how it could work at scale. The plastic was used to create a range of products for the retailer, including furnishings made from recycled PET. These were subsequently featured at various points of sale to help showcase the initiative, and educate visitors at their stores about how previously ‘single-use’ materials generated by retailer operations can be put to use.

Not only was this pilot included as a case study in marketing material, but crucially it helped Batch.Works refine their business model, as they identified that more effort would be needed in the initial selection of material streams to make the process scalable.

They are actively sharing their learnings with the industry more broadly, to help create further momentum. Having developed and refined a workshop aimed at retailers, they’ve created an asset for educating decision-makers in the consumer goods space. The workshop has been repeated with a large European client and their hands-on activities have been published as part of the EU Distributed Design Market Platform project.

Milo Mcloughlin-Greening, Batch.Works, Research & Sustainability OfficerThe ReLondon pilot project has been an extremely valuable stepping stone to move forward in our mission!

Lessons learned and next steps

Batch.Works’ project is a great illustration of how innovative manufacturing processes can be used to engage corporate customers around reuse of waste, while demonstrating how a meaningful reduction of waste can be achieved. By creating this demonstrator project, they were able generate new assets to attract new grants and support by other aligned organisations.

For other businesses seeking to implement similar projects, Batch.Work’s top tips are:

1. Find an ally: Look for key people who fit your customer profile and take them with you on your mission to make change.

2. Seeing is believing: Hands-on workshops break down barriers and generate great questions and conversations to bring concepts to life.

3. Compromise: Sometimes it is important to be reminded of the most important outputs of a project and make changes that enable you to keep moving towards “big picture” goals.

In 2022, Batch.Works has plans to continue the pioneering started through the Circular Pilot project. They have also secured new funding for their work via a number of innovation grants – one of which is for a £1.8M project which will be used towards their mission of creating a distributed network of manufacturing hubs to locally make products from recycled material.

Get in touch

If you’re interested in working with Batch.Works, get in touch with them using hello@batch.works.

ReLondon’s business transformation team continues to help small-and-medium sized businesses in London adopt the circular economy through our advisory support, grant schemes, and matchmaking services. Find out more about our fully funded business support programme at our website.